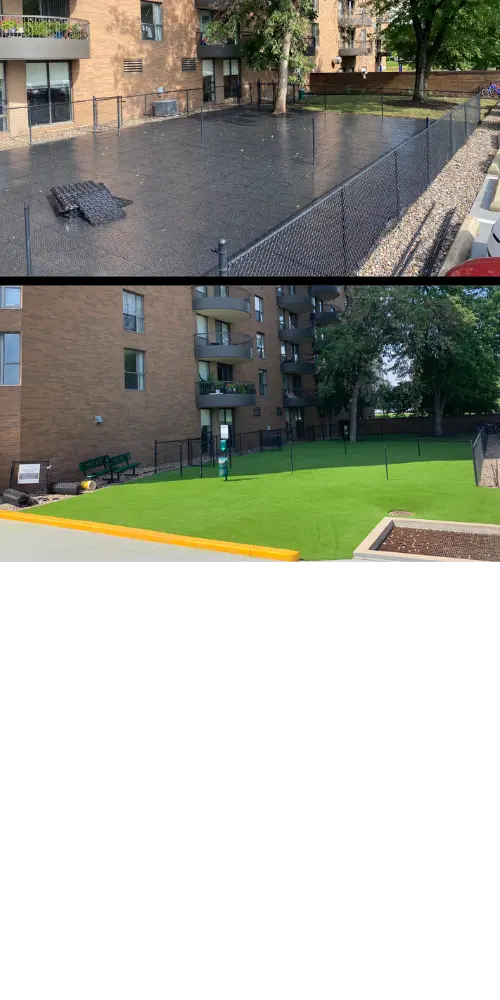

The RSI SPORTS Group has switched to recycled artificial turf as a raw material for their Turf Panel shock pads. With a ratio of two to one, the panels make an impact on both player performance and on the heap of discarded artificial turf that is awaiting recycling.

The move will make a major contribution to the waste policy of the European Union. The policy aims to reclaim as much as possible from existing products or projects and reuse the reclaimed material to produce a similar product of similar or even superior quality.

In short: it pursues the “re-use” or “reduce” before “recycle” principle.

Improved reclaiming process

Since 2021, the technology to recycle artificial turf has slowly made inroads in the outdoor plastic surfaces industry. Until then, all that could be made from reclaimed artificial turf were thick boards from which picnic tables, decking for bridges or flower boxes could be produced.

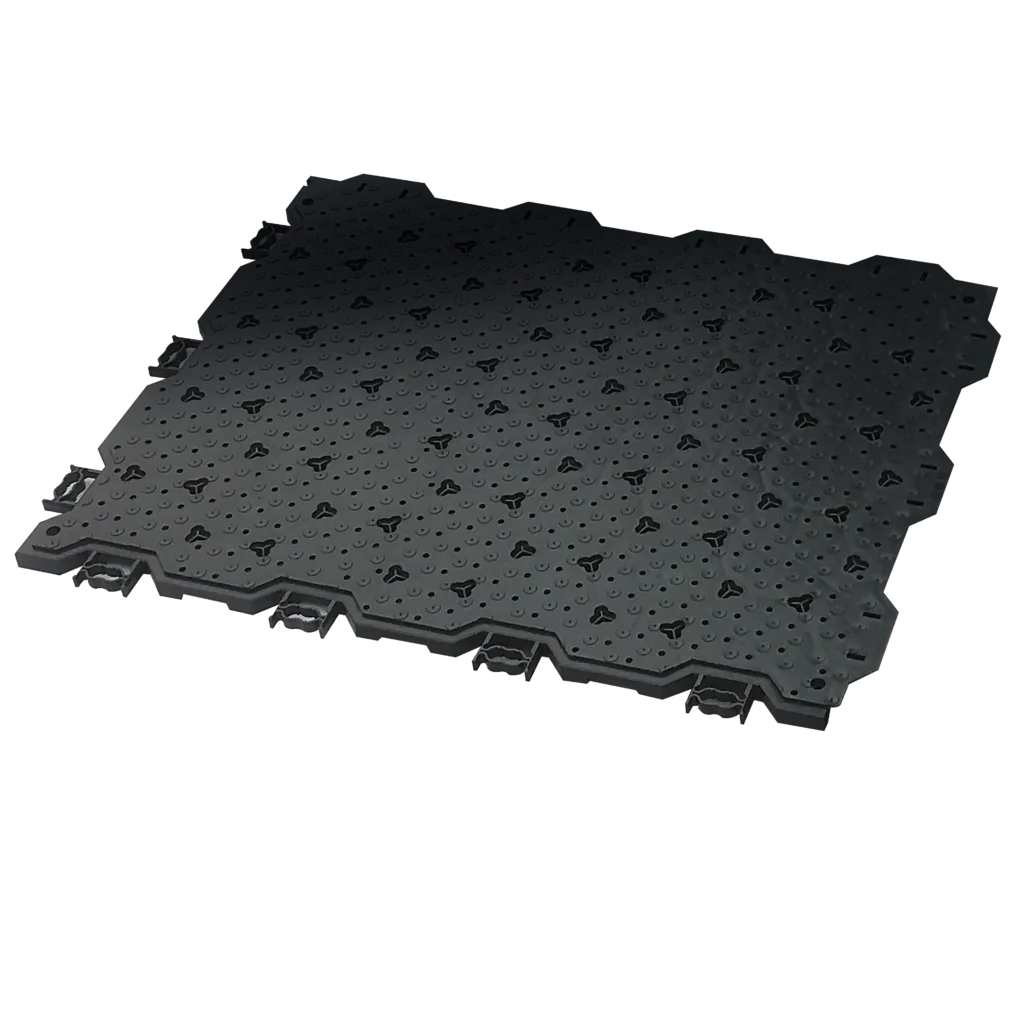

Together with artificial turf recycling company Re-Match, the RSI SPORTS Group has fine-tuned the recycling process. In doing so, Re-Match has managed to achieve a greater purity of their reclaimed products, which has allowed the RSI SPORTS Group to produce thinner, more flexible products like Turf Panels.

Leaving a significant dent

Compared to other products that used to be made of reclaimed artificial turf, Turf Panels contain a much higher volume of the reclaimed product.

“Each Turf Panel contains just under 4 kg of reclaimed artificial turf,” says Arnoud Fiolet of RSI SPORTS Group. Each panel measures 1 x 1 metre. Most artificial turf carpets contain just over 1 kg of yarn/m2.

“Just imagine how much material is available for reuse when using a reused artificial grass carpet,” Fiolet continues. Overall, an artificial turf carpet for football contains approximately 19,000 kg of material. The infill makes up most of it.

“It will take the processing of three to four full-sized artificial turf football pitches to produce enough panels to provide comfort and safety for one artificial turf pitch.”

With the two artificial turf recycling plants in the Netherlands processing approximately 500 artificial turf football fields per annum combined, that volume has to come mainly from abroad.

Both Re-Match and GBN AGR have already established networks to return their reclaimed products to the market.

“With the recycling capacity slowly increasing, I can safely say that our Turf Panels from reclaimed artificial turf will make a difference in the EU Waste Policy as well as the comfort and performance of players all over Europe.”